Latest Posts

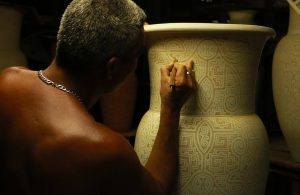

Curved Surfaces Made Easy

Applying a flat design to a curved object can feel like trying to wrap a football with a square piece of paper. For crafters and...

MOREThe Evolution Of Pottery Kilns

The history of pottery kilns is as rich and varied as the ceramics they produce. From their humble beginnings as simple pits to the sophisticated...

MOREPottery For The Masses

Mass production has revolutionised the way we consume products, including everyday ceramic items such as mugs, plates, and tiles. The process of mass-producing ceramics combines...

MOREDifferent Kilns, Different Result

Understanding the effects of different kiln firing methods is crucial for potters aiming to achieve specific aesthetic and functional results in their ceramic work. The...

MOREThe Art And Science Of Kiln-Made Pots

The vase on your table, that intricately designed plant pot on your shelf, the ceramic mug you hold every morning—all of these everyday items might...

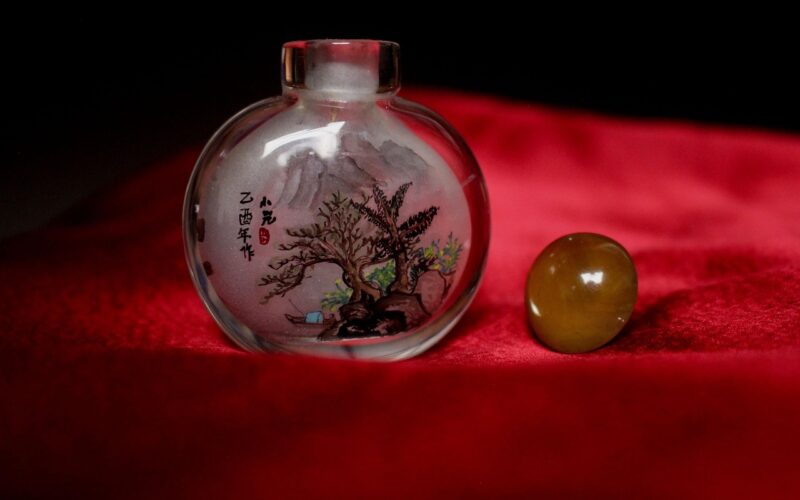

MOREPottery Before the Firing

Creating a finished piece of pottery is a long process, and much of it is done before the clay ever gets fired in a kiln....

MORECreating a Kiln Draft

Wood and gas kilns depend on air movement to create a greater amount of heat within the kiln. This is done by leaving gaps for...

MOREWood Fired Kilns

Pottery artists who have long studied their craft often prefer kilns that are heated using wood. They use the wood firing process to add a...

MOREElectric Kilns

Many new pottery artists choose electric kilns for several reasons. Control is one of the most important. An electric kiln offers a fine measure of...

MORE